Leadership is something we all respond to and it takes many forms.

Take a figure from history, such as Napoleon Bonaparte. A product of the ruling elite of his day, Napoleon underwent officer training and was undaunted by meeting calls to define the working structure of a post revolutionary state from scratch. The Codes Civils (sometimes referred to as the Napoleonic Codes) were an object lesson in structuring the edifice of a state at the start of a post-royal era (https://urbanfoodchains.uk/forging-urban-food-chains/). Bonaparte had the outward signs of a civic visionary and expected to lead from the front.

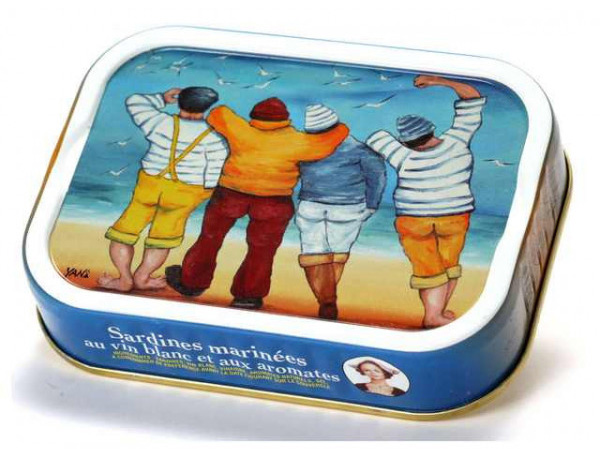

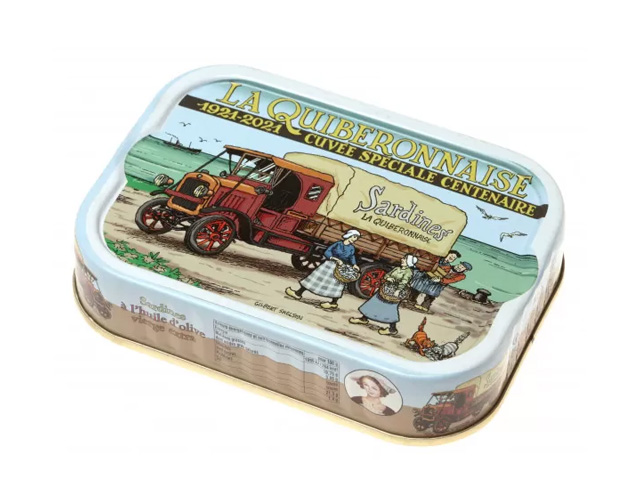

Employing a completely different set of skills, Nicolas Appert perfected the system of sealing food into bottles or cans and cooking it so thoroughly that the product would keep indefinitely. Sometimes referred to eponymously as Appertisation, the process has been used with very few changes, for more than two hundred years. Appert predated fellow Frenchman Louis Pasteur by just over 60 years and would not have predicted the link between heat treatment and killing pathogens that Pasteur would make in years to come.(https://urbanfoodchains.uk/time-travel-for-food-2/)

There are grounds to suppose that the Appertisation process was known to food producers, but not widely practiced in the 1790s. In place of a theoretical explanation for the incontrovertable success of the process, Appert constantly ran tests on batches of food, using bottles and stoppers of all sorts of material: ceramic, glass and metal. As the years progressed, his confidence in the process grew, as he learnt what cooking times different foods needed in a water jacket of boiling water. Nicolas Appert had been raised by an inn keeper working in Chalons-sur-Saone and was a competent chef. His entire working life was focussed on feeding people and by the 1790s Appert was working as a confiseur in a Paris suburb.

A confiseur is someone who cooks off food, usually with boiling water, to make range of “confits” or foods almost cooked to a mush. Confiserie refers to boiled sugar confectionery, while confits are table-ready dishes which can be sweet or savoury and typically capped off with a layer of fat. The aim is to cook off seasonal gluts, although meat-based confits had short shelf lives, since the melted grease did not offer any real protection to the dish. This was the reason for Appert’s interest in sealing his wide-necked bottles, in a bid to extend shelf life. Appert successfully got reliable results, which is why Appertisation is referred to as “Time Travel For Food” on this website.

Appert plied his trade as a confiseur and wholesale grocery from a workshop in rue des Lombards. He was a member of the militant Section des Lombards, who mobilised at moments of crisis during the revolution in Paris. An active Jacobin, Nicolas and his wife Elisabeth supported the revolutionary cause in practical ways, such as holding planning meetings in the workshop.

As readers will learn in the short history of Nicolas Appert, the confiseur was pulled into the Jacobin Terreur, saved only by the fact that Robespierre was executed 36 hours before Appert was due to go to the scaffold. The Appert household survive the latter years of the revolution: Nicolas is awarded an “encouragement” of 12,000 gold coins by Napoleon. This comes with a requirement to publish a manual to Appertisation at his own expense. Appert remained politically active during his life and was elected mayor of Ivry-sur-Seine.

Appert also makes a trip to England in 1814, at the height of the Napoleonic wars. The reason for the trip was for after-sales support for an English engineer who had licenced the process for commercial exploitation. The technology transfer had been overseen by Pierre Durand, a Bordeaux wine merchant turned intellectual property agent. Durand’s leadership style was simply blunt and overbearing. He met his match, however, in Bryan Donkin, his English client.

A highly regarded engineer, Donkin had undertaken work for the Fourdrinier brothers, Henri and Seely, to make their purchase of a design for a papermaking machine work in a paper mill environment. As his French clients faced bankruptcy and Donkin still had a workshop to keep in production, there was a pause in proceedings during which Donkin tried to stake a claim on what is known today as the Fourdrinier papermaking machine. Resourceful as ever, Donkin contrived to settle the name of the machine on the brothers, but retained control over the crucial detail that allowed him to sell working papermaking machines in his own name. Since he installed almost 200 machines across Europe, one can suppose that he was commercially successful. It should be added that Donkin also patented the dip pen and a number of nib designs, which generated far greater sales than could be earned from selling a papermaking machine. This management style is close to opportunistic, but shows a high level of resourceful thinking. Bryan Donkin’s grandson, called Bryan after his grandfather, developed and patented the Donkin gas valve, which is more widely known than Donkin senior’s achievements.