Until the latter years of the twentieth century, bacon followed a parallel path to the rest of the pig sector, taking its share of knocks on the way. Processors could sell as many loins of bacon as they could get their hands on, but they were held back by a balancing act, otherwise known as balancing the carcase.

On the slaughter line, every bacon pig was killed and split in two, before being cured as two sides of bacon. As late as the 1970s, the Danish industry body Danske Slagterier invested in a fresh fleet of refrigerated bacon trailers, most of which were worn out by the end of the century.

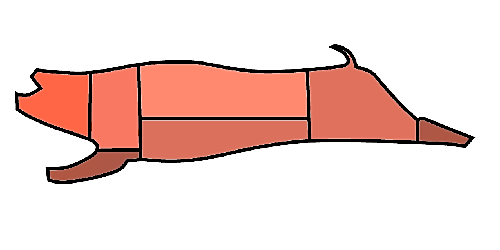

The traditional bacon pig, killed out before reaching the 90 kilo mark, used to travel to processors as a half carcase and was a weighty piece of cured meat that was butchered in many regional ways, all of which were sufficiently different for this to be a problem. It was the Dutch industry that broke the mould and changed the face of bacon processing for ever.

Taking pork loins from larger animals, the Dutch devised an ingenious system in which the loins were injected with brine and put in a heavy polythene bag. As the bagged product travelled, the curing process took effect, arriving on a slicing line as distinctive, large loins. This heralded the arrival of bacon rashers with “covering power” on a plate. The balancing act changed overnight and the side of bacon was history.

Leave a Reply