The Linlithgow committee provided four business snapshots based on live data (1923 figures..) to illustrate how the sector operated. There is no way of telling how much m, but the ones they published cast some light on the baking sector. Only theWar Office refused to share any data. The most detailed is based on figures from the National Association of Master Bakers’ and a number of local associations. The Industrial Co-operative group gave a terse rendering of the Co-op’s pricing structure, which differs in smalll but significant ways from retail rivals. Third is a glimpse of the War Office bakery, in Aldershot. It went to extraordinary lengths to say nothing. For the time being, I cannot locate where Butler Brothers traded, but the firm operated a number of branches from a central bakery.

The Linlithgow committee provided four business snapshots based on live data (1923 figures..) to illustrate how the sector operated. There is no way of telling how much m, but the ones they published cast some light on the baking sector. Only theWar Office refused to share any data. The most detailed is based on figures from the National Association of Master Bakers’ and a number of local associations. The Industrial Co-operative group gave a terse rendering of the Co-op’s pricing structure, which differs in smalll but significant ways from retail rivals. Third is a glimpse of the War Office bakery, in Aldershot. It went to extraordinary lengths to say nothing. For the time being, I cannot locate where Butler Brothers traded, but the firm operated a number of branches from a central bakery.

Get ready to work in farthings for a while, since this small, fiddly coin was the lowest common denominator of the day.

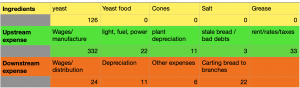

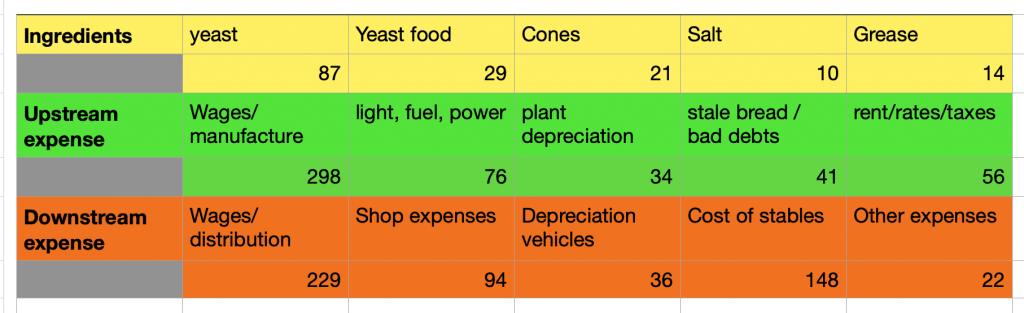

The Master Bakers give a fairly thorough view of the additional inputs needed to make a batch of bread from a sack of flour, bearing in mind that it consolidates data supplied by 26 local firms and 63 local associations.

National Association of Master Bakers

All the figures that follow are the additional costs for a batch of bread. The dry ingredients added to the 20 stone sack of flour were valued at 161 farthings or 3s/4d and a farthing. Upstream expenses for converting the flour totalled 112d, that is 9s/4d, ignoring a stray halfpenny. Downstream expenses including distribution for the resultant bread was 11 shillings. Total cost to convert a sack of flour left change out of £2/4 shillings. Stables accounted for just over three shillings to the costs of each batch, while depreciation on the capital for automotive vehicles was just a third of that.

Butler Bros.